MAZDA 3 TIMING CHAIN

2010 MAZDA3 MAZDASPEED3 Workshop Manual

DRIVE BELT REMOVAL INSTALLATION [LF, L5]

LF

1. Remove the aerodynamic under cover No.2 and splash shield as a single unit. (See 09-16-29 AERODYNAMIC

UNDER COVER NO.2 REMOVAL INSTALLATION.) (See 09-16-30 SPLASH SHIELD REMOVAL INSTALLATION.)

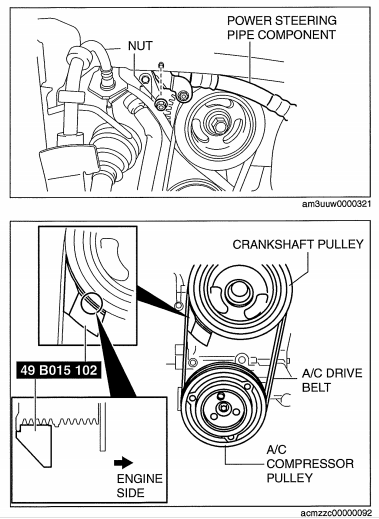

2. Remove the nut shown in the figure and set the

power steering pipe component out of the way.

3. Set the SST as shown in the figure.

Note

• Hold the SST by hand until it fits between the A/C drive belt and the crankshaft pulley.

4. Rotate the crankshaft pulley clockwise using a

wrench and remove the AlC drive belt.

Ale drive belt installation

1. Set the SST to the crankshaft pulley as shown in

the figure.

Note

• Hang the AlC drive belt on to the AlC

compressor pulley, then move the SST

upward along the crankshaft pulley.

2. Set the SST to the AlC compressor mount as

shown in the figure.

Note

Note

• During the AlC drive belt installation, if the

SST touches the part number-printed area

on the back of the AlC drive belt, the SST

may not be able to slide smoothly and the

A/C drive belt will be pulled inward excessively.

This will make it impossible to correctly

install the AlC drive belt to the groove of the

AlC compressor pulley. To prevent this,

adjust the AlC drive belt to the position

shown in the figure, then start the procedure.

3. After setting the SST, verify that the three parts of

AlC drive belt shown in the figure are hung on

each pulley.

4. Rotate the crankshaft pulley clockwise using a

wrench and install the AlC drive belt.

Caution

• Remove the SST (498015103)

immediately after it reaches the lower

side to prevent it from falling down and

being damaged.

5. Remove the SST (498015104)

6. Rotate the crankshaft pulley clockwise one time

or more to verify that the AlC drive belt is installed correctly.

• Do not turn the crankshaft pulley counter clockwise, otherwise the crankshaft pulley bolt could

loosen and the timing could change causing engine damage.

• If the AlC belt is not seated properly, push/pull the belt with a suitable tool in the direction where it would be

seated properly and then rotate the crank pulley clockwise until the belt is correctly seated. If this does not

correct the problem, remove the belt and install it again.

7. Install the nut shown in the figure.

| 8. Install the aerodynamic under cover No.2 and | |

splash shield as a single unit. (See 09-16-29

AERODYNAMIC UNDER COVER NO.2

REMOVAL/INSTALLATION.) (See 09-16-30

SPLASH SHIELD REMOVAL/INSTALLATION.)

Generator drive belt removal

1. Remove the AlC drive belt. (See 01-1 OA-6 AlC drive belt removal.)

2. Turn the center of the auto tensioner pulley

counterclockwise to release tension to the drive

belt tension.

3. Remove the generator drive belt.

Generator drive belt installation

1. Install a generator drive belt.

2. Install the A/C drive belt. (See 01-1 OA-6 AlC drive belt removal.)

1. Remove the aerodynamic under cover No.2 and splash shield as a single unit. (See 09-16-29 AERODYNAMIC

UNDER COVER NO.2 REMOVAL INSTALLATION.) (See 09-16-30 SPLASH SHIELD REMOVAL

INSTALLATION.)

2. Rotate the drive belt auto tensioner in the

direction shown in the figure and remove the drive

belt.

Installation

1. Install the drive belt.

2. Install the aerodynamic under cover No.2 and splash shield as a single unit. (See 09-16-29 AERODYNAMIC

UNDER COVER NO.2 REMOVAL INSTALLATION.) (See 09-16-30 SPLASH SHIELD REMOVAL

INSTALLATION.)

DRIVE BELT AUTO TENSIONER INSPECTION [LF, LS]

1. Remove the generator drive belt with the AlC drive belt still installed and set it out of the way. (See 01-1 OA-6

DRIVE BELT REMOVAL INSTALLATION [LF, LS].)

2. Verify that the drive belt auto tensioner moves

smoothly in the operational direction.

• If it does not move smoothly, replace the drive

belt auto tensioner. (See 01-1 OA-4S ENGINE

DISASSEMBLY/ASSEMBLY [LF, LS].)

3. Turn the drive belt auto tensioner pulley by hand

and verify that it rotates smoothly.

• If it does not move smoothly, replace the drive

belt auto tensioner. (See 01-1 OA-4S ENGINE

DISASSEMBLY/ASSEMBLY [LF, LS].)

4. Install the generator drive belt. (See 01-1 OA-6

DRIVE BELT REMOVAL INSTALLATION [LF, LS].)

L5

1. Remove the drive belt. (See 01-1 OA-6 DRIVE BELT REMOVAL/INSTALLATION [LF, LS].)

2. Verify that the drive belt auto tensioner moves

smoothly in the operational direction.

• Replace the drive belt auto tensioner if

necessary. (See 01-1 OA-4S ENGINE

DISASSEMBLY/ASSEMBLY [LF, LS].)

3. Rotate the drive belt auto tensioner pulley by

hand and verify that it rotates smoothly.

• Replace the drive belt auto tensioner if

necessary. (See 01-1 OA-4S ENGINE

DISASSEMBLY/ASSEMBLY [LF, LS].)

4. Install the drive belt. (See 01-1 OA-6 DRIVE BELT

REMOVAL/INSTALLATION [LF, LS].)

VALVE CLEARANCE INSPECTION [LF, LS]

1. Remove the battery cover. (See 01-17A-2 BATTERY REMOVAL/INSTALLATION [LF, LS].)

2. Disconnect the negative battery cable.

3. Remove the plug hole plate. (See 01-1 OA-S PLUG HOLE PLATE REMOVAL/INSTALLATION [LF, LS].)

4. Disconnect the wiring harness.

S. Remove the ignition coils. (See 01-18A-2 IGNITION COIL REMOVAL/INSTALLATION [LF, LS].)

6. Remove the spark plugs. (See 01-18A-3 SPARK PLUG REMOVAL/INSTALLATION [LF, LS].)

7. Remove the ventilation hose.

8. Remove the oil level gauge.

9. Remove the cylinder head cover. (See 01-1 OA-21 TIMING CHAIN REMOVAL/INSTALLATION [LF, LS].)

10. Remove the aerodynamic under cover No.2 and splash shield as a single unit. (See 09-16-29 AERODYNAMIC

UNDER COVER NO.2 REMOVAL/INSTALLATION.) (See 09-16-30 SPLASH SHIELD REMOVAL/

INSTALLATION.)

11 . Measure the valve clearance.

Note

• Make sure to note down the measured values for choosing the suitable replacement tappets.

(1) Turn the crankshaft clockwise so that the No.1 piston is at top dead center (TDC) of the compression

stroke.

(2) Measure the valve clearance at A in the B A B

figure.

Valve clearance [Engine cold]

IN: 0.22-0.28 mm {0.009-0.011 in}

EX: 0.27-0.33 mm {0.011-0.012 in}

(3) If the valve clearance is out of the standard

value, adjust it.

(4) Turn the crankshaft 360 0 clockwise so that the

No.4 piston is at TDC of the compression

stroke. am3uuw0000216

(S) Measure the valve clearance at B in the

figure.

Valve clearance [Engine cold]

IN: 0.22-0.28 mm {0.009-0.011 in}

EX: 0.27-0.33 mm {0.011-0.012 in}

(6) If the valve clearance is out of the standard value, adjust it. (See 01-1 OA-11 VALVE CLEARANCE

ADJUSTMENT [LF, LS].)

12. Install in the reverse order of removal.

MECHANICAL [LF, LS]

VALVE CLEARANCE ADJUSTMENT [LF, LS]

1. Remove the battery cover. (See 01-17A-2 BATTERY REMOVAUINSTALLATION [LF, LS].)

2. Disconnect the negative battery cable.

3. Remove the plug-hole plate. (See 01-10A-S PLUG HOLE PLATE REMOVAUINSTALLATION [LF, LS].)

4. Disconnect the wiring harness.

S. Remove the ignition coils. (See 01-18A-2 IGNITION COIL REMOVAUINSTALLATION [LF, LS].) .’.

6. Remove the spark plugs. (See 01-18A-3 SPARK PLUG REMOVAUINSTALLATION [LF, LS].) .

7. Remove the ventilation hose.

8. Remove the oil level gauge.

9. Remove the cylinder head cover. (See 01-10A-21 TIMING CHAIN REMOVAUINSTALLATION [LF, LS].)

10. Remove the aerodynamic under cover No.2 and splash shield as a single unit. (See 09-16-29 AERODYNAMIC

UNDER COVER NO.2 REMOVAL INSTALLATION.) (See 09-16-30 SPLASH SHIELD REMOVAL

INSTALLATION.)

11. Remove the generator drive belt with the AlC drive belt still installed and set it out of the way. (LF)

12. Remove the drive belt. (LS) (See 01-10A-6 DRIVE BELT REMOVAUINSTALLATION [LF, LS].)

13. Remove the engine front cover lower blind plug.

14. Remove the engine front cover upper blind plug.

1S. Disconnect the drive shaft (RH) from joint shaft,

set the drive shaft (RH) out of the way. (MTX)

16. Remove the cylinder block lower blind plug, and

install the SST.

17. Rotate the crankshaft in the direction of the

engine rotation so that the No.1 piston is at top

dead center (TDC) of the compression stroke.

(Until the counterweight contacts SST and stops.)

18. Loosen the timing chain using the following procedure.

(1) Insert a suitable bolt (M6 X 1.0, length 25-

35 mm {1.0-1.3 in}) into the engine front

cover upper blind plug and tighten it until it

contacts the chain tensioner arm, and then

rotate it back one turn. (Set the bolt slightly

away from the chain tensioner arm so that it

does not contact it.)

(2) Using the cast hexagon on the exhaust

camshaft, apply force counterclockwise to

facilitate unlocking the chain tensioner

ratchet.

(3) Using a Hex bit socket (2.5 mm {o.Oga in}) or

T15 Torx bit socket, unlock the chain

tensioner ratchet so that it can be lifted up.

(4) Using the cast hexagon on the exhaust

camshaft, apply force in the direction of the

engine rotation to increase tension on the

chain.

Note

Note

• The chain tensioner rack is compressed

using the chain tension generated by

applying force to the exhaust camshaft in the

direction of the engine rotation.

(5) Screw in the bolt set in Step 1 approx. 5 mm

{0.2 in} and secure the tensioner arm with the

rack compressed.

Note

• The racket has not been unlocked if the bolt

cannot be pressed in approx. 5 mm {0.2 in}.

NOT UNLOCK UNLOCK

BOLT (M6 x1.0,

LENGTH

25-35 mm

{1.0-1.3 in})

NOT UNLOCK UNLOCK

• If the tensioner arm cannot be secured, return the bolt to its original position and repeat the procedure

from Step 3.

19. Fix the exhaust camshaft using a wrench on the

cast hexagon, and loosen the camshaft sprocket

bolt.

20. Remove the exhaust camshaft sprocket bolt,

exhaust camshaft sprocket, and washer as a

single unit.

Caution

• Perform the work carefully so that the

washer does not drop out.

21. Remove the OCV. (See 01-1 OA-20 OIL

CONTROL VALVE (OCV) REMOVAL!

INSTALLATION [LF, L5].)

22. Loosen the camshaft cap bolts in two or three

steps in the order shown in the figure and remove

the camshaft cap.

Note

• The camshaft caps are to be kept ordered

for correct reassembly in their original

positions. Do not mix the caps.

23. Remove the camshafts for the intake and exhaust

sides.

24. Remove the tappet.

25. Install an appropriate tappet based on the results

of the valve clearance inspection.

Selected tappet = Removed tappet thickness +

Measured valve clearance – Standard valve

clearance

Valve clearance [Engine cold]

IN: 0.22-0.28 mm {0.009-0.011 in}

EX: 0.27-0.33 mm {0.011-0.012 in}

26. Verify that No.1 cylinder is at TOC of the

compression stroke. (Position counterweight contacts

27. Apply the gear oil (SAE No.90 or equivalent) to

each journal of the cylinder head as shown in the

figure.

28. Install the camshaft with No.1 cylinder aligned

with the TOC position.

29. Apply the gear oil (SAE No.90 or equivalent) to

each journal of the camshaft as shown in the

figure.

30. Temporarily tighten the camshaft cap bolts evenly

in 2-3 steps.

31. Tighten the camshaft cap bolts in the order shown

in the following two steps.

Tightening procedure

Step 1: 5.0-9.0 N·m {51-91 kgf·cm, 45-79

in·lbf}

Step 2: 14-17 N·m {1.5-1.7 kgf.m, 11-12

ft·lbf

32. Install the OCV. (See 01-1 OA-20 OIL CONTROL

VALVE (OCV) REMOVAL INSTALLATION [LF,

LS].)

33. Install the exhaust camshaft sprocket bolt,

exhaust camshaft sprocket, and a new washer as

a single unit.

Caution

• Install a washer to the fourth or fifth

thread of the exhaust camshaft sprocket

bolt being careful not to drop the washer.

• Do not tighten the camshaft sprocket bolt

at this stage. Verify the valve timing

before performing the bolt tightening.

34. Install the SST on the camshaft as shown in the

figure.

35. Remove the installation bolt for the engine front

cover upper blind plug (M6 X 1.0 length 25-

35mm {1.0-1.3 in}), and apply tension to the

timing chain.

•

•

36. Fix the exhaust camshaft using a wrench on the

cast hexagon, and tighten the sprocket bolt.

Tightening torque

69-75 N·m {7.1-7.6 kgf.m, 51-55 ft.lbf}

37. Remove the SST from the camshaft.

38. Remove the SST installed in the cylinder block

lower blind plug hole.

39. Rotate the crankshaft clockwise two turns and

inspect the valve timing.

• If not aligned, loosen the camshaft sprocket

bolt and repeat the procedure from Step 34.

40. Install the cylinder block lower blind plug.

Tightening torque

18-22 N·m {1.9-2.2 kgf.m, 14-16 ft.lbf}

41. Connect the drive shaft (RH) to joint shaft. (MTX)

(See 03-13-3 DRIVE SHAFT REMOVAL

INSTALLATION.)

42. Apply the silicone sealant and install the engine

front cover upper blind plug.

Caution

• Install the engine front cover upper blind

plug before the applied silicone sealant

starts to harden.

Tightening torque

8-11 N·m {82-117 kgf·cm, 71-101 in·lbf}

43. Install a new engine front cover lower blind plug.

Tightening torque

10-14 N·m {102-142 kgf·cm, 89-123

in.lbf}

44. Install the drive belt. (L5) (See 01-1 OA-6 DRIVE

BELT REMOVAL INSTALLATION [LF, L5].)

45. Install the generator drive belt. (LF) (See 01-1 OA-

6 DRIVE BELT REMOVAL INSTALLATION [LF,

L5].)

46. Install the aerodynamic under cover No.2 and

47. Install the cylinder head cover. (See 01-1 OA-21 TIMING CHAIN REMOVAUINSTALLATION [LF, L5].)

48. Install the oil level gauge.

49. Install the ventilation hose.

50. Install the spark plugs. (See 01-18A-3 SPARK PLUG REMOVAUINSTALLATION [LF, L5].)

51. Install the ignition coils. (See 01-18A-2 IGNITION COIL REMOVAUINSTALLATION [LF, L5].)

52. Connect the wiring harness.

53. Install the plug hole plate. (See 01-10A-5 PLUG HOLE PLATE REMOVAUINSTALLATION [LF, L5].)

54. Connect the negative battery cable.

55. Install the battery cover. (See 01-17A-2 BATTERY REMOVAUINSTALLATION [LF, L5].)

• Hot engines and oil can cause severe burns. Be careful not to burn yourself during removal

installation of each component.

• Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

| sparks and flames away from fuel. • Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line Safety Procedure”. | • | I |

I •

1. Verify that the battery is fully charged. (See 01-17A-4 BATTERY INSPECTION [LF, LS].)

• Recharge it if necessary. (See 01-17A-S BATTERY RECHARGING [LF, LS].)

2. Warm up the engine to the normal operating temperature.

3. Perform “Fuel Line Safety Procedures”. Leave the fuel pump relay removed. (See 01-14A-4 BEFORE

SERVICE PRECAUTION [LF, LS].)

4. Remove the plug hole plate. (See 01-1 OA-S PLUG HOLE PLATE REMOVAL/INSTALLATION [LF, LS].)

S. Remove the ignition coils. (See 01-18A-2 IGNITION COIL REMOVAL/INSTALLATION [LF, LS].)

6. Remove the spark plugs. (See 01-18A-3 SPARK PLUG REMOVAL/INSTALLATION [LF, LS].)

7. Connect a compression gauge into the spark plug

hole.

8. Fully depress the accelerator pedal and crank the

engine. ~

9. Note down the maximum gauge reading.

10. Inspect each cylinder as above.

Compression [LF]

Standard: 1,400 kPa {14.28 kgf/cm2, 203.1

psi} [300 rpm]

Minimum: 980 kPa {10.0 kgf/cm2, 142.2 psi}

| [300 rpm] Maximum difference between cylinders: |

196.1 kPa {2.0 kgf/cm2, 28.5 psi}

Compression [LS]

Standard: 1,324 kPa {13.S0 kgf/cm2, 192.0 psi} [300 rpm]

Minimum: 927 kPa {9.4S kgf/cm2, 134 psi} [300 rpm]

Maximum difference between cylinders: 196.1 kPa {2.0 kgf/cm2, 28.5 psi}

• If the measured value is less than the limited value, or there is a cylinder whose compression value varies

from that of other cylinders by 196.1 kPa {2.0 kgf/cm2, 28.5 psi} or more, add a small amount of engine oil

through the spark plug hole. Then measure the compression pressure and perform the respective

operations for the following cases.

If the compression increases, the piston, the piston rings, or cylinder wall may be worn and overhaul is required.

– If the compression stays low, a valve may be stuck or improperly seated and overhaul is required.

– If the compression in adjacent cylinders stays low, the cylinder head gasket may be damaged or the

cylinder head distorted and overhaul is required.

11. Disconnect the compression gauge.

12. Install the following parts.

(1) Spark plugs. (See 01-18A-3 SPARK PLUG REMOVAL/INSTALLATION [LF, LS].)

(2) Ignition coils. (See 01-18A-2 IGNITION COIL REMOVAL/INSTALLATION [LF, LS].)

(3) Plug hole plate. (See 01-1 OA-S PLUG HOLE PLATE REMOVAL/INSTALLATION [LF, LS].)

(4) Fuel pump relay. (See 01-14A-4 BEFORE SERVICE PRECAUTION [LF, LS].)

• Variable valve timing actuator can not be disassembled because it is a precision unit.

1. Remove the battery cover. (See 01-17A-2 BATTERY REMOVAUINSTALLATION [LF, LS].)

2. Disconnect the negative battery cable.

3. Remove the plug hole plate. (See 01-10A-S PLUG HOLE PLATE REMOVAUINSTALLATION [LF, LS].)

4. Disconnect the wiring harness.

S. Remove the ignition coils. (See 01-18A-2 IGNITION COIL REMOVAUINSTALLATION [LF, LS].)

6. Remove the spark plugs. (See 01-18A-3 SPARK PLUG REMOVAUINSTALLATION [LF, LS].)

7. Remove the ventilation hose.

8. Remove the oil level gauge.

9. Remove the cylinder head cover. (See 01-10A-21 TIMING CHAIN REMOVAUINSTALLATION [LF, LS].)

10. Confirm that notch of the rotor and notch of the

cover at the variable valve timing actuator are

aligned and fitted.

• If the notch of the rotor and notch of the cover

are not aligned, turn the crankshaft clockwise

two rotations. Verify that notch of the rotor and

notch of the cover are aligned.

• If the both notches are still not aligned, replace

the variable valve timing actuator. (See 01-1 OA-

18 VARIABLE VALVE TIMING ACTUATOR

REMOVAUINSTALLATION [LF, LS].)

• If, when turning the crankshaft, there is a hitting

position, it means that the actuator is not secured. Replace the actuator. (See 01-1 OA-18 VARIABLE VALVE

TIMING ACTUATOR REMOVAUINSTALLATION [LF, LS].)

11. Install in the reverse order of removal.

• Variable valve timing actuator can not be disassembled because it is a precision unit.

• Intake camshaft sprocket is integrated with the variable valve timing actuator and cannot be disassembled.

1. Refer to the ‘VALVE CLEARANCE ADJUSTMENT’ procedure and remove the variable valve timing actuator and

the camshaft on the intake side as a single unit. (See 01-1 OA-11 VALVE CLEARANCE ADJUSTMENT [LF, LS].)

2. Remove the variable valve timing actuator.

(1) Mark the camshaft and variable valve timing

actuator as shown in the figure to make sure

they are installed in their original position.

(2) Secure the camshaft in a vise.

(3) Loosen the variable valve timing actuator

tightening bolt.

3. Install a new washer.

4. Install the variable valve timing actuator.

Note

• When the variable valve timing actuator is

replaced with a new one, mark it in the same

location as the old one.

(1) Secure the camshaft in a vise.

(2) Align the marks of the camshaft and variable

valve timing actuator.

(3) Tighten variable valve timing actuator

tightening bolt.

Tightening torque

69-75 N·m {7.1-7.6 kgf.m, 51-55 ft.lbf}

am3uuw0000222

5. Refer to the “VALVE CLEARANCE ADJUSTMENT” procedure and install the variable valve timing actuator and

the camshaft on the intake side as a single unit. (See 01-1 OA-11 VALVE CLEARANCE ADJUSTMENT [LF,LS].)

Note

• If the alignment marks on the variable valve timing actuator are not available, refer to the “TIMING CHAIN

ASSEMBLY” in the engine workshop manual and perform the sprocket position alignment again.

1. Remove the battery cover. (See 01-17A-2 BATTERY REMOVAUINSTALLATION [LF, LS].)

2. Disconnect the negative battery cable.

3. Remove the plug hole plate. (See 01-10A-S PLUG HOLE PLATE REMOVAUINSTALLATION [LF, LS].)

4. Disconnect the OCV connector.

5. Measure the resistance between terminals A and

B using an ohmmeter.

OCV coil resistance

6.9-7.9 ohms [20°C {68°F}]

• If not as specified, replace the OCV. (See 01-

10A-20 OIL CONTROL VALVE (OCV)

REMOVAUINSTALLATION [LF, LS].)

6. Install in the reverse order of removal.

Spool Valve Operation Inspection

tm1

1. Remove the OCV. (See 01-1 OA-20 OIL CONTROL VALVE (OCV) REMOVAUINSTALLATION [LF, LS].)

2. Verify that the spool valve in the OCV is in the

maximum valve timing retard position as indicated

in the figure.

• If not as specified, replace the OCV. (See 01-

10A-20 OIL CONTROL VALVE (OCV)

3. Verify that the battery is fully charged. (See 01-17A-4 BATTERY INSPECTION [LF, LS].)

• If not as specified, recharge the battery. (See 01-17A-S BATTERY RECHARGING [LF, LS].)

Note

• When applying battery positive voltage

between the OCV terminals, the connection

can be either of the following:

Positive battery cable to terminal A,

negative battery cable to terminal B

Positive battery cable to terminal B,

negative battery cable to terminal A

4. Apply battery positive voltage between the OCV

terminals and verify that the spool valve operates

and moves to the maximum valve timing advance

position.

• If not as specified, replace the OCV. (See 01-

SPOOL VALVE

S. Stop applying battery positive voltage and verify

that the spool valve returns to the maximum valve

timing retard position.

• If not as specified, replace the OCV. (See 01-

(MAXIMUM VALVE TIMING ADVANCE POSITION)

6. Install the OCV. (See 01-10A-20 OIL CONTROL

VALVE (OCV) REMOVAL INSTALLATION [LF, LS].)

OIL CONTROL VALVE (OCV) REMOVAL INSTALLATION [LF, LS]

1. Remove the battery cover. (See 01-17A-2 BATTERY REMOVAUINSTALLATION [LF, LS].)

2. Disconnect the negative battery cable.

3. Remove the plug hole plate. (See 01-1 OA-S PLUG HOLE PLATE REMOVAUINSTALLATION [LF, LS].)

4. Disconnect the wiring harness.

S. Remove the ignition coils. (See 01-18A-2 IGNITION COIL REMOVAUINSTALLATION [LF, LS].)

6. Remove the ventilation hose.

7. Remove the oil level gauge.

8. Remove the cylinder head cover. (See 01-10A-21 TIMING CHAIN REMOVAUINSTALLATION [LF, LS].)

9. Remove in the order indicated in the table.

10. Install in the reverse order of removal.

IOCV installation bolt

2 OCV

TIMING CHAIN REMOVAL INSTALLATION [LF, LS]

id0110a7801000

1. Remove the battery cover. (See 01-17A-2 BATTERY REMOVAL/INSTALLATION [LF, LS].)

2. Disconnect the negative battery cable.

3. Remove the plug hole plate. (See 01-1 OA-S PLUG HOLE PLATE REMOVAL/INSTALLATION [LF, LS].)

4. Disconnect the wiring harness.

S. Remove the ignition coils. (See 01-18A-2 IGNITION COIL REMOVAL/INSTALLATION [LF, LS].)

6. Remove the spark plugs. (See 01-18A-3 SPARK PLUG REMOVAL/INSTALLATION [LF, LS].) •

7. Remove the ventilation hose. I I •

8. Remove the coolant reserve tank with the hose still connected and set it out of the way. (See 01-12A-7

COOLANT RESERVE TANK REMOVAL/INSTALLATION [LF, LS].)

9. Remove the front wheel and tire. (RH) (See 02-10-1 GENERAL PROCEDURES (SUSPENSION).)

10. Remove the aerodynamic under cover No.2 and splash shield as a single unit. (See 09-16-29 AERODYNAMIC

UNDER COVER NO.2 REMOVAL/INSTALLATION.) (See 09-16-30 SPLASH SHIELD REMOVAL/

INSTALLATION.)

11. Remove the nut shown in the figure and set the power steering pipe component out of the way.

LF

L5

{82-1 01, 71-88}

POWER STEERING

PIPE COMPONENT

N·m {kgf.cm, in·lbf}

12. Remove the drive belt. (See 01-10A-6 DRIVE BELT REMOVAL/INSTALLATION [LF, LS].)

13. Remove the crankshaft position (CKP) sensor. (See 01-40A-30 CRANKSHAFT POSITION (CKP) SENSOR

REMOVAL/INSTALLATION [LF, LS].)

14. Remove the AIC compressor with the cooler hose still connected and secure it using wire or rope so that it is

out of the way. (LF) (See 07-11-18 AlC COMPRESSOR REMOVAL/INSTALLATION.)

1S. Disconnect the drive shaft (RH) from joint shaft, set the drive shaft (RH) out of the way. (MTX) (See 03-13-3

DRIVE SHAFT REMOVAL/INSTALLATION.)

16. Remove in the order indicated in the table.

17. Install in the reverse order of removal.

18. Start the engine. And inspect and adjust the following:

• Leakage of engine oil. (See 01-11A-3 ENGINE OIL LEVEL INSPECTION [LF, LS].)

• Runout and contact of pulley and belt.

• Verify the ignition timing, idle speed and idle mixture. (See 01-1 OA-3 ENGINE TUNE-UP [LF, L5].)

LF

96-104

{9.8-10, 71-76}

+87-93°

@:8-11 N·m

{82-112 kgf.cm,

71-97 in·lbf}

| 1 | Dipstick |

| 2 | Cylinder head cover (See 01-10A-24 Cylinder Head Cover Removal Note.) (See 01-1 OA-30 Cylinder Head Cover Installation Note.) |

| 3 | Crankshaft pulley lock bolt (See 01-1 OA-24 Crankshaft Pulley Lock Bolt Removal Note.) (See 01-1 OA-29 Crankshaft Pulley Lock Bolt Installation Note.) |

| 4 | Crankshaft pulley |

| 5 | Water pump pulley |

| 6 | Drive belt auto tensioner |

7-13 N·m

{72-132 kgf.cm,

62-115 in·lbf}

01-10A-22

| 7 | No.3 engine mount (See 01-10A-25 No.3 Engine Mount Removal Note.) (See 01-1 OA-28 NO.3 Engine Mount Installation Note.) |

| 8 | Front oil seal (See 01-10A-34 FRONT OIL SEAL REPLACEMENT [LF, L5].) |

| 9 | Engine front cover (See 01-1 OA-27 Engine Front Cover Installation Note.) |

| 10 | Chain tensioner (See 01-1 OA-26 Chain Tensioner Removal Note.) |

| 11 | Tensioner arm |

19-25

{2.0-2.5,

8.0-9.5 N·m

{82-96 kgf.cm,

71-84 in·lbf}

N·m {kgf.m, ft·lbf}

am3uuw0000296

MECHANICAL [LF, LS]

| 12 | Chain guide |

| 13 | Timing chain (See 01-1 OA-26 Timing Chain Installation Note.) |

| 14 | Oil pump chain tensioner |

L5

71-93

{7.3-9.4,

51BJ

75-104

i..® 56 {7.7-10, – 76}

96-104

{9.8-10, 71-76}

+87-93°

7-13 N·m

{72-132 kgf.cm,

62-115 in.lbf}

@:8-11 N·m

{82-112 kgf.cm,

71-97 in.lbf}

| 1 | Dipstick |

| 2 | Cylinder head cover (See 01-1 OA-24 Cylinder Head Cover Removal Note.) (See 01-10A-30 Cylinder Head Cover Installation Note.) |

| 3 | Crankshaft pulley lock bolt (See 01-1 OA-24 Crankshaft Pulley Lock Bolt Removal Note.) (See 01-1 OA-29 Crankshaft Pulley Lock Bolt Installation Note.) |

| 4 | Crankshaft pulley |

| 5 | Water pump pulley |

| 15 | Oil pump sprocket (See 01-1 OA-26 Oil Pump Sprocket Removal/ Installation Note.) |

| 16 | Oil pump chain |

| 17 | Crankshaft sprocket |

| 6 | Idler pulley |

| 7 | Idler pulley |

| 8 | No.3 engine mount (See 01-10A-25 NO.3 Engine Mount Removal Note.) (See 01-1 OA-28 No.3 Engine Mount Installation Note.) |

| 9 | Front oil seal (See 01-10A-34 FRONT OIL SEAL REPLACEMENT [LF, L5].) |

| 10 | Engine front cover (See 01-1 OA-27 Engine Front Cover Installation Note.) |

| 11 Chain tensioner (See 01-10A-26 Chain Tensioner Removal Note.) |

| 12 Tensioner arm |

| 13 Chain guide |

| 14 Timing chain (See 01-10A-26 Timing Chain Installation Note.) |

Cylinder Head Cover Removal Note

1. Remove the purge solenoid valve installation

bracket with the evaporative hose still connected

and set it out of the way.

2. Loosen the cylinder head cover bolts in the order

shown in the figure.

Crankshaft Pulley Lock Bolt Removal Note

1. Rotate the crankshaft in the direction of the

engine rotation and remove the cylinder block

lower blind plug when the No.1 cylinder is at the

point prior to top dead center (TDC) of

compression, then install the SST.

2. Rotate the crankshaft in the direction of the

engine rotation so that the No.1 piston is at TDC

of the compression stroke. (Until the

counterweight contacts SST and stops.)

3. Hold the crankshaft pulley by using the SSTs.

Mazda 3 BM BN 2013-2018 Workshop-Manual Download

Mazda 3 Mazdaspeed3 MPS Workshop-Manual 2008-2013 Download

HOME