AUDI TFSI ENGINE TECHNOLOGIES

Tfsi engines 20th Aachen Colloquium Automobile and Engine Technology 2011

TFSI Engines from Audi -Innovative Technologies in Current and Future-

Dr. Rainer Wurms, Michael Jung, Dr. Stephan Adam,

Dr. Stefan Dengler, Dr. Thomas Heiduk, Axel Eiser

AUDI AG, Ingolstadt

Summary

Over the last 7 years the turbocharged direct-injection SI engine – designated TFSI

by Audi – has successfully penetrated the market for passenger car SI engines.

Thanks to its many significant advantages, TFSI technology will replace most other

SI engine concepts in the near future, just as TDI technology did in the past.

As the pioneer and technology leader in TFSI, Audi has continually enhanced its

TFSI technology since its first production fitting of a direct turbocharged engine in

Europe and NAR in 2004. In 2011 Audi launched what is already its third generation

of four-cylinder inline TFSI engines onto the market. Once again, this third generation

incorporates many innovative technologies applied to an SI engine for the first time

anywhere in the world.

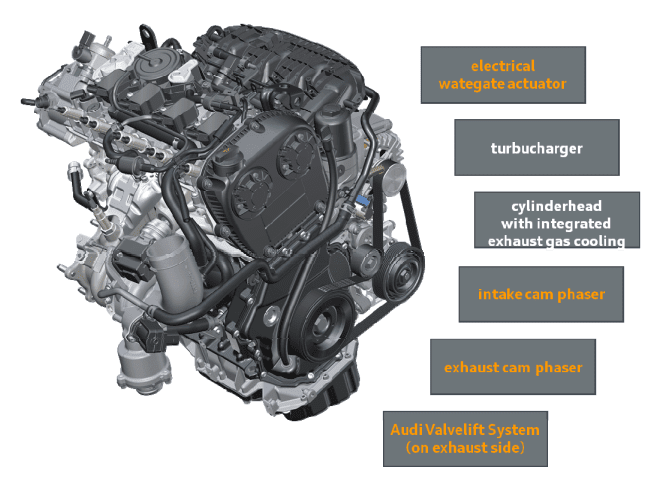

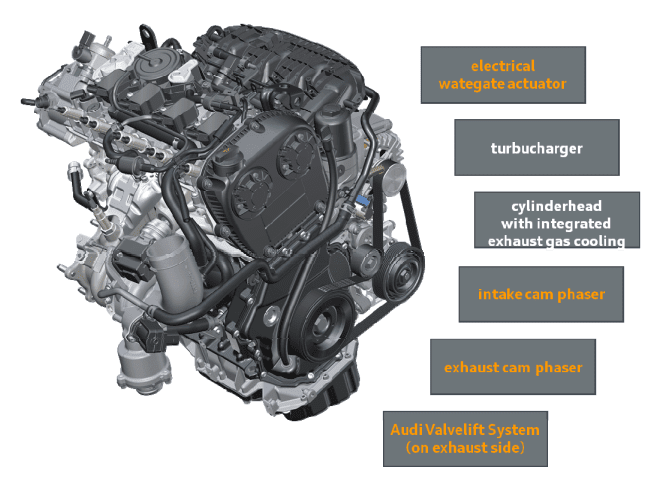

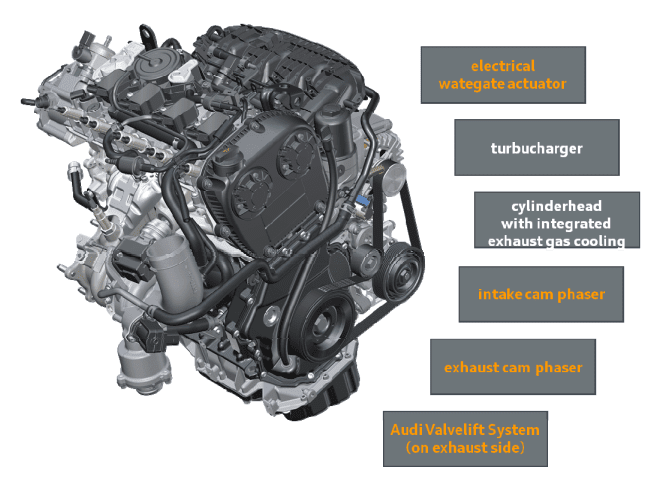

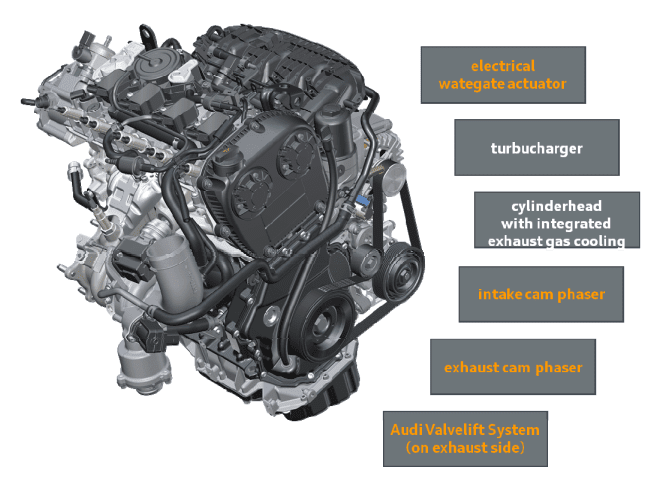

In addition to the Audi Valvelift System, for the first time the engine has a cylinder

head with integrated exhaust manifold and complete cylinder firing sequence

separation, an electric wastegate actuator, an innovative thermal management

system and a completely new mixture preparation system in order to comply with

future exhaust emission standards.

The presentation details the design and working principle of the new technologies in

the third-generation TFSI engine. It also looks ahead to potential further technology

advances for future SI engines.

1 Introduction

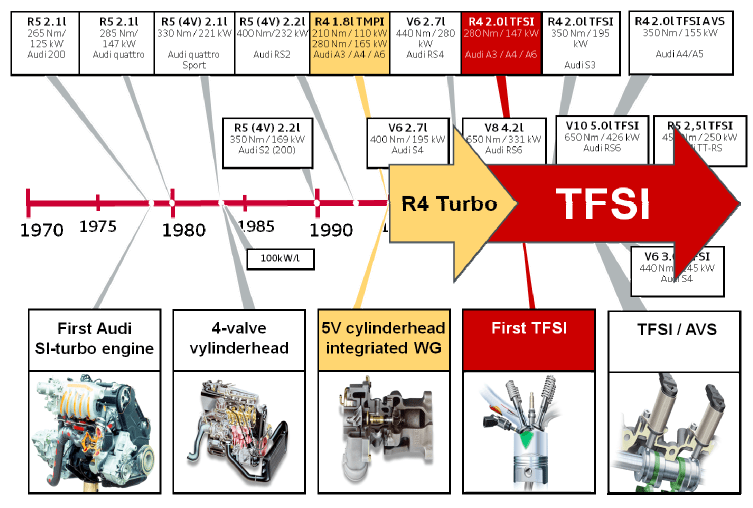

Exhaust gas turbocharging has a long-standing tradition at Audi. Since the initial

launch of a turbocharged petrol engine in 1979, Audi has been continually advancing

its turbocharger technology.

There were two outstanding events, however, which dictated the future of Audi

engines – and ultimately then also of petrol engines in general. Whereas in the

period from 1979 to 1995 Audi turbocharged engines were deployed only in specialist

sports designs and in a few high-end applications, the launch of the four-cylinder

inline 1.8l 5VT in 1995 marked the breakthrough for the turbocharged engine as a

widely accepted standard power unit for passenger cars.

The introduction of TFSI technology in 2004 then saw the beginning of a new era in

petrol engine technology.

2 20th Aachen Colloquium Automobile and Engine Technology 2011

Fig. 1: History of petrol engine turbocharging at Audi

TFSI enabled torque and power output – and especially low-end torque and dynamic

responsiveness – to be significantly improved, meaning that TFSI engines suffered

hardly any disadvantages compared to induction engines with the same power

output. Quite the contrary in fact: the high torque even at low engine speeds made

TFSI engines highly appealing to drivers. The high compression ratios made possible

by TFSI, and the downsizing and down speeding advantages it delivered, brought

further significant reductions in consumption both under testing and in customer

applications.

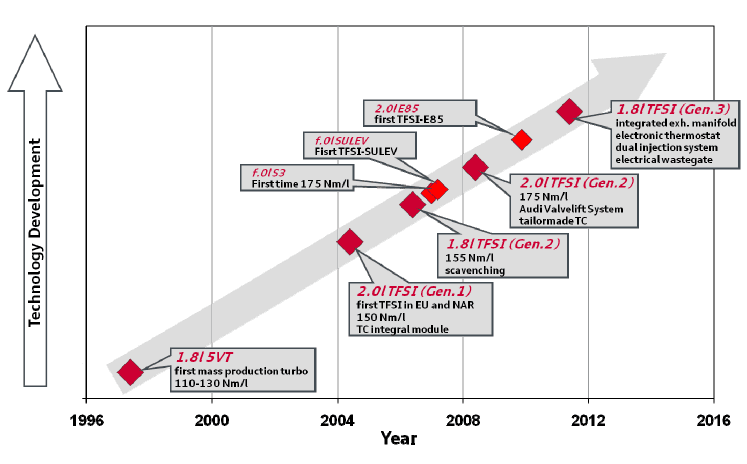

In the years following 2004, Audi continually advanced its TFSI technology. Key

milestones were the launch of the EA888 engine series in 2006, marking the second

generation of TFSI technology and for the first time featuring a flushing charge cycle.

The combination of TFSI and the Audi valve lift system implemented for the first time

in 2008 represented a further major advance. This enabled a specific torque of 175

Nm/l to be realized for the first time in a non-sport design. Thanks to the significant

increases in low-end torque and the improvements in dynamics, the 2.0l TFSI engine

could be combined with long gear ratios and retained its good levels of driveability

even from low engine speeds. Maximizing down speeding potential also enabled

consumption to be greatly reduced.

Other milestones in the history of TFSI from Audi were the launch of the S3 engine in

2007 and the introduction of a TFSI design onto the North American market – the

latter development also for the first time enabling compliance with stringent SULEV

exhaust emission limits. In 2010 a Flexfuel version of the 2.0l TFSI engine was

launched, capable of running on fuels with different ethanol contents up to and

including E85.

In the summer of 2011 Audi launched the third generation of its four-cylinder inline

TFSI engine onto the market. This engine generation is again characterised by a

large number of innovative technologies, some of which are being deployed for the

first time in mass production. The next section deals in detail with the technologies

and performance data of the third generation.

Development of Audi petrol engine turbocharger technology (four-cylinder inline engines 1995-2012)

|

Fig. 2: |

Development of Audi petrol engine turbocharger technology (four-cylinder inline engines 1995-2012) |

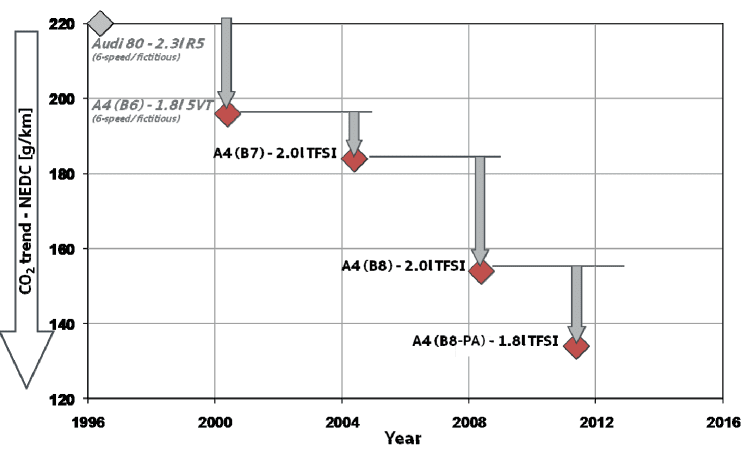

Alongside the developments in technology, the launch of turbocharged and TFSI

engines also significantly reduced the fuel consumption of Audi models as well as of

many other Group models. As shown in Figure 3, the NEDC consumption (presented

here for a B-class saloon (Audi 80 / Audi A4) with a 6-speed manual gearbox) of the

latest version of the A4 is 86 g CO2, or almost 40%, lower than a notionally calculated

1995 model with a five-cylinder inline 2.3l induction engine. And at the same time all

key performance characteristics were also improved – in some cases significantly.

The major portion of the reduction in CO2 demonstrated (over 85%) was achieved by

advances in engine development. Alongside improvements to mechanical and

thermodynamic efficiency, the implementation of thermal management measures and

an automatic start/stop function, most of the CO2 improvements were brought about

4 20th Aachen Colloquium Automobile and Engine Technology 2011

by the introduction and advancement of turbocharging and TFSI technology.

Downsizing and down speeding strategies alone reduced the NEDC CO2 emissions of

the B-class models investigated here by 50 g.

The trend in CO2 emissions of Audi turbocharged petrol engines (B-class 1995-2012)

|

Fig. 3: | Trend in CO2 emissions of Audi turbocharged petrol engines (B-class 1995-2012) |

2 The third generation 1.8l EA888 engine

As already described, in the summer of 2011 Audi put into production the third

generation of its four-cylinder inline TFSI engine. The first of this new generation is

the 1.8l EA888 TFSI in the new Audi A4. The 1.8l TFSI once again incorporates a

large number of new and innovative technologies, some of which are being deployed

for the first time in a mass production engine.

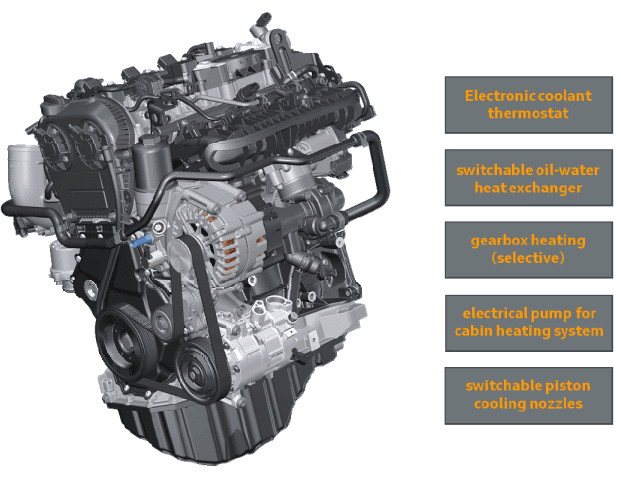

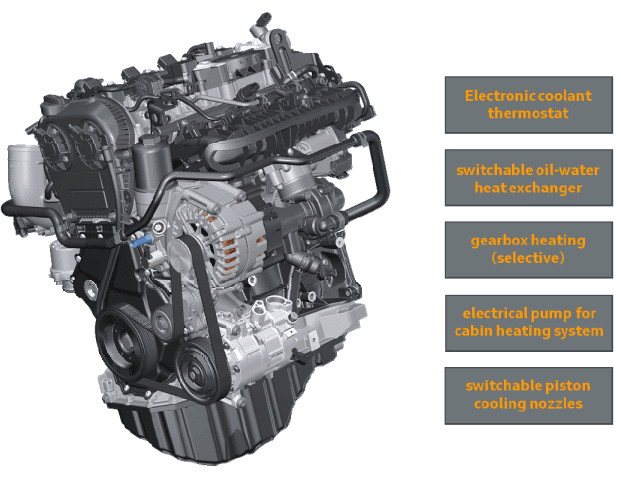

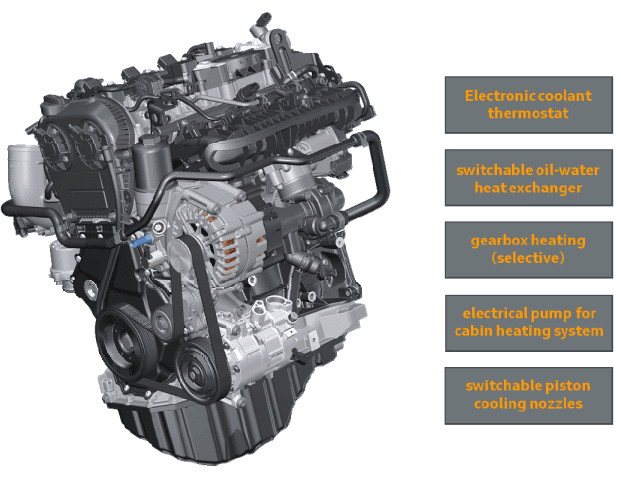

2.1 Base engine – Optimised friction and thermal management

Many new, efficiency-enhancing measures have been implemented even in the base

engine model. As shown in Figure 4, the main components relevant to friction were

completely redesigned. In addition to a conventional optimisation of the piston-liner

friction, the balance shafts were in part mounted on roller bearings. Also, the

crankshaft bearings were reduced in size and, more specifically, adapted to the load

demands of the 1.8l TFSI engine. The complete oil circuit was also revised, and the

pressure and volumetric flow controlled oil pump was reconfigured. For the first time

switchable piston cooling nozzles are also employed, in order to realise additional

20th Aachen Colloquium Automobile and Engine Technology 2011 5

potential particularly during the heat-up phase and under low loads. This represents a

further implementation of variability in the crank drive as in other areas.

Fig. 4: 1.8l EA888 Gen.3 – Measures to optimize friction

Further significant advantages in terms of fuel consumption were achieved by means

of an actively controlled thermal management system (Figure 5). One of the technical

highlights of this is the first use of an electronic coolant thermostat (Figure 6). This

makes it possible to leave the coolant standing after the engine starts, as a result of

which the engine warms up much more rapidly. Once a modelled component

temperature is reached, a first rotary slide opens a small cross-section, causing a

mini-volumetric flow to slowly move the coolant. The engine continues to warm up

much faster than at the otherwise normally much higher volumetric flows.

As the engine continues to warm up, in a likewise temperature-controlled sequence

first the oil/water heat exchanger is activated by way of the electronic coolant

thermostat and then the gear oil heat exchanger is activated by an additional

switching valve. Only when the specified coolant temperature of 107°C has been

reached does the coolant thermostat mix-in cold water from the main cooler, so

regulating the coolant temperature under map control to the specified temperature.

As well as controlling the heat-up process in order to optimise fuel consumption, the

coolant thermostat also enables demand-based engine temperature control. As

already mentioned, in the lower part load range a high, fuel consumption optimised

coolant temperature of 107°C is set. Under higher loads the coolant temperature is

gradually reduced based on map control. Under full load, the electronic coolant

thermostat can very rapidly lower the coolant temperature down to 85°C, thereby

reducing the tendency to knock and so likewise delivering benefits in terms of

efficiency. This means that, ultimately, the optimum coolant temperature to achieve

maximum efficiency can be set for any operating point.

The thermal management system in the Audi A4 is rounded off by an autonomous

heating system. A switching valve and an electric heating pump enable the heating

circuit to be deactivated or, as necessary, allow heating mode to be activated while

there is still coolant standing in the engine block or if the volumetric flow by the main

coolant pump is low. In the latter case the heat is drawn only from the cylinder head

with the integrated exhaust manifold. In both cases, the engine block in particular –

and thus the piston liner assembly – heats up much faster than without the thermal

management measures, resulting in further fuel consumption benefits.

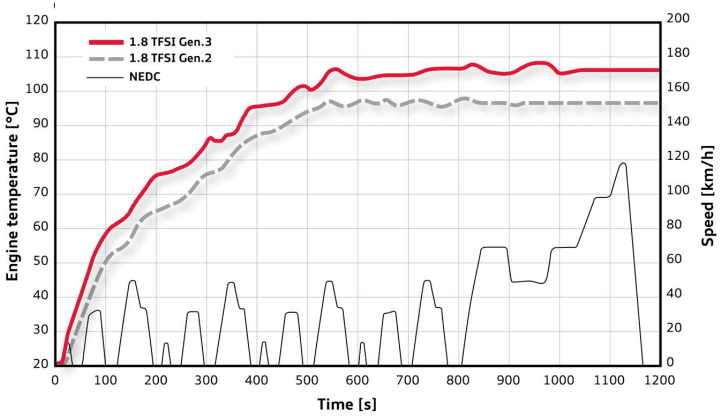

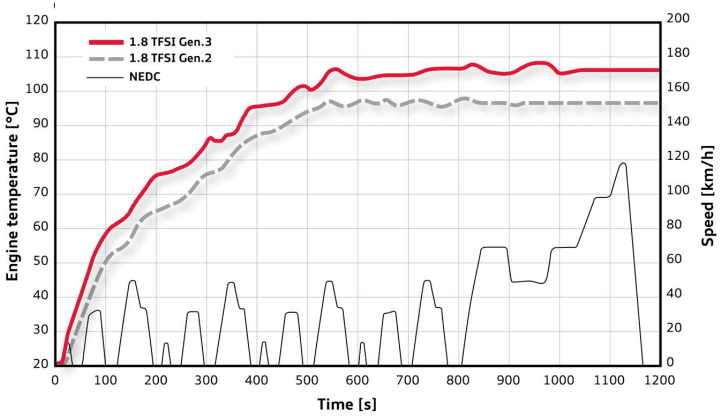

|

Fig. 7: |

1.8l EA888 Gen.3 – Temperature curve in the NEDC with autonomous heating compared to 1.8l EA888 Gen.2 |

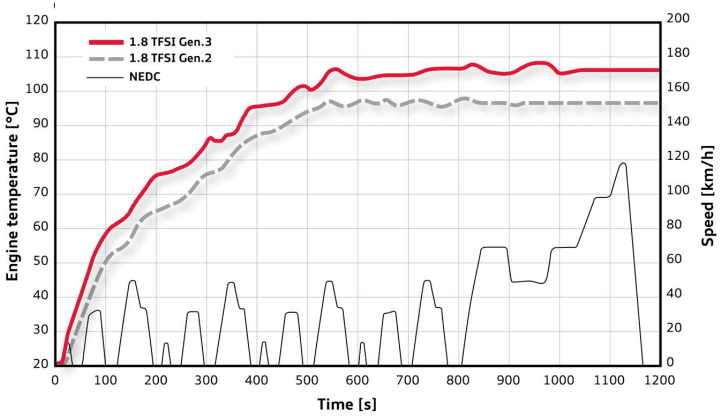

Figure 7 shows the temperature curve of the third generation 1.8l EA888 in the

NEDC with autonomous heating compared to the second generation 1.8l EA888. The

more rapid rise in coolant temperature and the higher operating temperature of the

third generation engine are clear to see. Overall, enhancements to the thermal

management system helped cut the engine’s CO2 emissions in the NEDC by

approximately 2.5 g.

8 20th Aachen Colloquium Automobile and Engine Technology 2011

2.2 Combustion process and Thermodynamics

For the new third-generation EA888 engine the tried and proven TFSI combustion

process has been optimized further in a wide variety of aspects, both to further

improve robustness in terms of knocking and spark advance at mean pressures

increased up to 22 bar and to optimize combustion stability under the changed

conditions due to the integrated exhaust manifold in terms of residual gas behavior

and air ratio. In addition to this, the charge motion induced by the inlet port without

the tumble flap activated has been increased once again. As a result of the

optimized, slightly retracted position of the high-pressure injector, mixture

homogenization has been further improved, and at the same time a positive side-effect has been achieved in the reduction of the temperature load on the injector.

To achieve the required increase in power output allied to much improved

spontaneity and optimised full load fuel efficiency, the Audi valvelift system (twostage valve lift change-over of the exhaust camshaft) familiar from the 2.0l TFSI

predecessor engine was adopted and for the first time combined with a camshaft

adjuster on the exhaust side to provide maximum degrees of freedom in controlling

the charge cycle.

Fig. 8: 1.8l EA888 Gen.3 – Dual injection system

The third generation EA888 also for the first time features a dual fuel injection system

(Figure 8). Alongside a high-pressure direct-injection system with system pressure

increased from 150 to 200 bar, a low-pressure injection system has also been

20th Aachen Colloquium Automobile and Engine Technology 2011 9

integrated into the VTS (Variable Tumble System) flange which injects into the upper

area of the inlet ducts. Using the dual injection system allows the optimum fuel

injection to be selected in every load range (intake manifold injection under low loads

and direct injection under medium and high loads), so enabling a further reduction in

CO2 emissions while at the same time complying with future emission limits.

Fig. 9: 1.8l EA888 Gen.3 – Combustion process / Thermodynamics

As shown in Figure 9, alongside the usual variability in terms of ignition and injection

timing and wastegate control, the third generation EA888 now exhibits seven

additional variabilities so as to ensure optimum charge motion and mixture

preparation, as well as attaining the ideal mixture of air, fuel and residual gas, at

every operating point, thereby maximising thermodynamic efficiency. Implementing

an engine with so many degrees of freedom poses an extreme challenge to the

applications engineers.

2.3 Turbocharging and full-load performance

Alongside direct fuel injection, turbocharging is the core technology of the TFSI

technology. In this context, too, a wide range of new technologies have been

deployed alongside detail optimisation measures. Figure 10 shows the principal full

load control components.

10 20th Aachen Colloquium Automobile and Engine Technology 2011

Fig. 10: 1.8l EA888 Gen.3 – Turbocharging control components

A technical ‘highlight’ in this respect is without doubt the cylinder head with integrated

exhaust manifold (Figure 11), put into production by Audi for the first time in the third

generation EA888.

Fig. 11: 1.8l EA888 Gen.3 – Cylinder head with integrated exhaust manifold

Integrating the exhaust manifold into the water-cooled cylinder head means that the

exhaust gas is cooled on its way to the turbocharger. In combination with a cast steel

20th Aachen Colloquium Automobile and Engine Technology 2011 11

turbocharger, the engine can thus be run in the upper load range at approximately

100°K higher combustion temperatures, which means thermodynamic efficiency can

be significantly improved and consumption under high load can be greatly reduced.

Achieving a thermodynamically and thermomechanically optimised package of gas

ducts and cooling ducts posed a particular challenge during the development of the

cylinder head, especially with regard to production feasibility and castability on a

mass production scale.

With regard to coolant transport, a strategy of ‘keeping the coolant flow under control

at all times’ was pursued right from the start. The coolant flows are adjusted and

divided by way of defined cross-sections in the cylinder head gasket, with 75% of the

total coolant flow being routed via the integrated exhaust manifold. The remaining

25% bypasses the integrated exhaust manifold, flowing directly from the cylinder

block into the cylinder head. High flow speeds in the coolant ducts permit greater

heat transport and thus intensive cooling, particularly of the critical web areas, and so

safely prevent local boiling of the coolant.

Fig. 12: 1.8l EA888 Gen.3 – Combined simulation “CCM+” (CFD and FEM)

From the very beginning, development work was supported by the intensive use of

CFD calculations. To be able to simulate the complex effects inside the integrated

exhaust manifold with sufficient accuracy, alongside established CFD and FEM

methods a number of new simulation methods also had to be developed, enabling

CFD and FEM calculations to be combined and optimisation measures to be

interlinked.

First, classic CFD simulations were used to produce the basic design of the gas and

water cores and combined with FEM methods to thermomechanically optimise the

12 20th Aachen Colloquium Automobile and Engine Technology 2011

cylinder head. As there is intensive coupling between the exhaust gas and cooling

water flows and heat transport in the aluminium within a very tight space – that is to

say, involving extreme temperature gradients – in this project all three areas (gas,

water, aluminium) were also calculated in a single simulation model for the first time

(Figure 12, left). This methodology enables retroactive effects of the component

temperatures on the fluid temperatures and the resultant heat flows to be simulated

more accurately.

The development of the integrated exhaust manifold cylinder head revealed that, as

well as the stationary cooling design, the load cycles involving negative load and

speed changes are also a key factor. Immediately after such a change of operating

state, firstly the large amount of heat stored in the material is discharged into the

cooling water and, secondly, the cooling water volumetric flow and pressure

decrease dramatically due to the slow water pump speed caused by the low engine

revs. The hot water jacket areas are particularly at risk of boiling in this context, which

in the long term may result in harm to the cooling water.

Extreme cases of such load cycles, as well as rapid shutdowns, were analysed both

on the test rig and by simulation. In the final integrated exhaust manifold

configuration, from an integral viewpoint a comparable level to the predecessor

engine was attained in terms of short-time boiling intensity (Figure 12, right). This

simulation methodology, too, was deployed for the first time in the course of the

integrated exhaust manifold development.

Fig. 13: 1.8l EA888 Gen.3 – Gas transport in integrated exhaust manifold and

turbocharger

20th Aachen Colloquium Automobile and Engine Technology 2011 13

Extensive CFD simulations and measurements were also carried out on the fired

engine in order to configure the gas ducts. To prevent interaction between the

cylinders in the lower and mid engine speed ranges especially, a long ignition

sequence separation, extending into the turbocharger, was implemented. At the

same time, the gas ducts were configured such that the flow takes place with as little

loss as possible, and is always routed directly towards the turbine (Fig. 13).

Ultimately, this reduced the flow losses and push-out work, as well as lowering the

residual gas content in the cylinders, across the entire engine speed range. The

impulse energy onto the turbine was also increased. Overall, despite the restrictions

imposed by the package, the integrated exhaust manifold configuration delivers

almost identical performance to that of an external exhaust manifold in terms of flow

technics and gas dynamics.

The turbocharging system is an entirely newly developed mono-scroll turbocharger

(Figure 14). The aim of the turbocharger design was to combine good low-end torque

with maximum power output and very high performance. The basis for this design

was the RHF4 turbocharger from IHI, with various improvements made to the rotor

assembly, the spirals, the housings and to all the flow-carrying parts and

components.

Fig. 14: 1.8l EA888 Gen.3 – Turbocharger with electric wastegate

The turbocharger turbine housing is made of cast steel 1.4837, and so permits a

turbine inlet temperature of 980°C. For the first time at this high exhaust gas

14 20th Aachen Colloquium Automobile and Engine Technology 2011

temperature, it was possible to fabricate the turbine wheel in Inconel 713 C instead of

MAR. The compressor rotor is milled from a solid block, which delivers advantages

such as greater high-speed strength and better acoustics.

The third generation 1.8l EA888 features the first use by Audi of an electric

wastegate actuator. This enables even faster and more precise control of the

wastegate than the previously used actuator with a pressure cell. Active opening of

the wastegate under part load enables the base charge pressure to be lowered. This

results in additional savings in fuel consumption both in the NEDC and in customer

applications. The active opening of the wastegate also permits faster catalytic

converter heat-up, resulting in lower cold-start emissions.

For the first time at Audi the oxygen sensor has been positioned ahead of the

turbocharger turbine. This allows for a considerably earlier dew point end, and thus

early enabling of lambda control after the engine starts, as well as providing good

individual cylinder recognition.

Extensive CAE optimisation work was carried out on both the turbine and compressor

sides. Figure 15 shows both CFD simulation models in one view. On the turbine side,

the CFD simulations in the complete system are analysed with the integrated exhaust

manifold gas routing in the cylinder head, the turbine housing (including impeller), the

wastegate, the oxygen sensor upstream of the turbine and the exhaust system

through to downstream of the close-coupled main catalytic converter. The aims here

were to optimise the integrated exhaust manifold gas routing in conjunction with the

turbine inlet, the flow to the oxygen sensor, the wastegate design, and to ensure a

very good flow to the catalytic converter.

Fig. 15: 1.8l EA888 Gen.3 – CFD simulations of the turbocharger system

20th Aachen Colloquium Automobile and Engine Technology 2011 15

On the compressor side the CFD model includes the air induction, the compressor

including all inlet points (e.g. from the crankcase ventilation) as well as the dump

valve and the charge air duct. The aim was firstly to develop gas flow to and from the

compressor that was as loss-free as possible and neutral with regard to the

performance of the compressor, and secondly to find the best possible position for

the inlet points and the recirculation valve. In this context the simulations identified

considerable potential both with regard to reduce pressure losses and in terms of

compressor efficiency.

On completion of the extensive optimisation work, the turbocharger of the third

generation 1.8l EA888 engine exhibited better low-end torque, and in particular faster

responsiveness, than other turbocharger design concepts currently on the market

and in development, while attaining the same power and torque data. It thus

represents the current benchmark in turbocharger technology.

The outstanding result is also illustrated again in Figure 16, in which the full-load

torque and dynamic torque curve of the new third generation 1.8l EA888 engine are

compared against the data of its predecessor and against the second generation 2.0l

EA888. The significant advantages over the second generation 1.8l engine are clear

to see, as is the fact that the third generation 1.8l engine is practically equal to the

larger-capacity second generation 2.0l both in terms of torque level and dynamic

torque curve.

Fig. 16: 1.8l EA888 Gen.3 – Full-load torque and dynamics compared to 1.8l

EA888 Gen.2 and 2.0l EA888 Gen.2

16 20th Aachen Colloquium Automobile and Engine Technology 2011

For the new Audi A4 in the 125/132 kW class, this ultimately made it possible to

replace the existing 2.0l engine with the new 1.8l unit, and so not only realise the

aforementioned improvements in thermodynamic and mechanical efficiency but also

to achieve a further improvement in CO2 emissions of 6 to 7 g in the NEDC by means

of downsizing, without customers having to accept compromises in terms of

performance.

3 Future developments in TFSI technology

The questions for the future will be how the direct-injection petrol engine will continue

to be developed, and what potential it offers in particular with regard to further

reductions in CO2 emissions.

3.1 Base engine – Optimised friction and thermal management

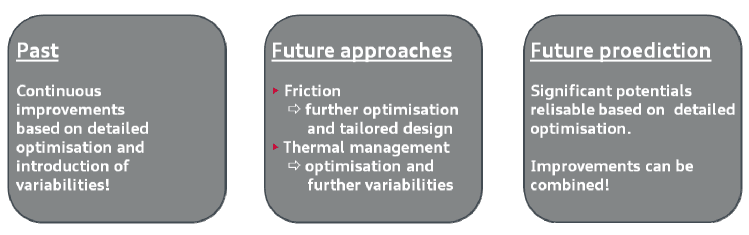

As already demonstrated, fuel consumption improvements were achieved in the past

in relation to optimisation of friction and thermal management based on continuous

detail optimisation and the introduction of variability.

|

Fig. 17: | Further development of TFSI technology – Friction and thermal management |

There remains significant potential to be realised in future. Detail optimisation in

relation to engine friction will mean that engines will be tailored ever more precisely to

their specific applications. In terms of thermal management, although the early

approaches implemented have realised considerable potential, there still remains

significant potential for improvement. This is, however, conditional on the introduction

of further variability. The improvements in fuel consumption brought by optimising

friction and by thermal management fundamentally offer the benefit of reducing

losses while having little cross-effect on other optimisation measures, so that the

respective gains can be combined almost completely.

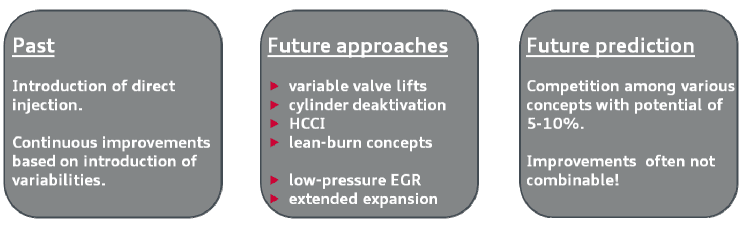

3.2 Combustion process and thermodynamics

With regard to the combustion process and thermodynamics, improvements in the

past were achieved thanks to the introduction of direct fuel injection and large

20th Aachen Colloquium Automobile and Engine Technology 2011 17

numbers of variabilities, as well as by stretching the operating parameters to their

limits. In conjunction with the conventional =1 combustion processes, however, the

existing potential in this regard has now been largely exhausted.

But for some considerable time there have been new technical ideas in circulation

which seek to realise further potential based on new combustion methods or cylinder

deactivation. But the lean-burn methods, homogeneous charge compression ignition

(HCCI), variable valve lift control or cylinder shut-off, all target the lower part-load

range and utilise similar physical effects (derestriction, reduction of heat losses).

Consequently, it is in most cases pointless to combine the methods as, once a

technology has delivered its advantages, few further benefits are achievable.

|

Fig. 18: | Further development of TFSI technology – Combustion process and thermodynamics |

Low-pressure EGR or methods involving extended expansion (Miller/Atkinson Cycle)

tend to promise more in the way of efficiency advantages in the mid and upper load

ranges. These two methods also utilise similar physical principles, so ultimately once

again it only makes sense to apply one of the two. Combining them would deliver

very little additional gain. The disadvantages of both methods, however, are that they

require an increased charge pressure and that they reduce the full-load torque and

nominal power output. To compensate for this, in order to avoid compromises in

terms of performance, turbocharger design concepts involving increased charge

pressure supply are required.

So, all in all, there remains significant potential for reducing consumption by

thermodynamics-related measures as in other areas. The potential is estimated at 5

to 10 percent, and will doubtless be gradually realised in future.

However, one point needs to be considered in this context. In the past, car-makers

had great difficulty in introducing new combustion processes, as – in addition to their

advantages – they in most cases also entailed a wide range of disadvantages

relating to exhaust gas after treatment or combustion stability and smooth running,

and as a consequence were mostly withdrawn from the market again after a short

time. In this light, it is doubtless more likely that there will be an evolution of the

current =1 combustion processes rather than any revolutionary introduction of new

methods.

18 20th Aachen Colloquium Automobile and Engine Technology 2011

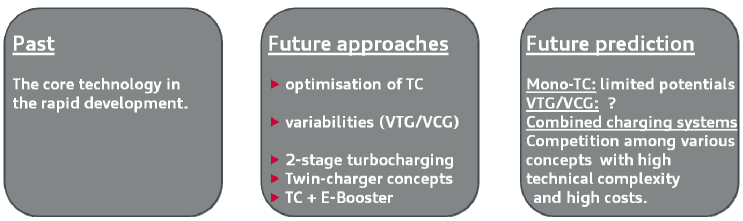

3.3 Turbocharging

The core technology in the rapid developments seen over recent years was without

doubt turbocharging – also of course in conjunction with the introduction of variability

enabling the charge cycle to be controlled ever more optimally. On the other hand,

due to that rapid past development some limits have today already been reached.

As a consequence of the improvements in torque of TFSI engines, in many vehicle

design concepts the gear ratios have been extended so far in recent years that

further extension would bring no benefit, so little further downspeeding potential

exists. For mono-turbocharger concepts, in Audi’s view a specific torque of

approximately 175 Nm/l today likewise represents a useful limit, in order still to

safeguard adequate low-end and starting-off torque and dynamic responsiveness,

thereby ensuring good driveability in all situations.

Consequently, in Audi’s view the key challenges of the future in terms of

turbocharging concepts are to improve starting-off and low-end torque and dynamic

torque build-up – that is to say, ultimately, the rapid availability of high charge

pressures even from very low engine speeds. In this respect, too, there are already a

number of technical ideas in circulation for the future development of turbocharging

technology.

Fig. 19: Further development of TFSI technology – Turbocharging

However, the turbochargers themselves are today for the most part fully optimised,

and as such offer only limited potential. Turbocharger developers are investigating a

number of technologies in terms of aerodynamic or mechanical optimisation, but at

present they are frequently revealing only minor potential improvements at still very

high cost, so their application in mass production would appear unlikely at any time in

the near future.

Research has likewise been ongoing for more than 10 years with regard to variability

on the turbine and compressor side, though to date only in a few number of cases

they have been turned into production applications, as they often offer few

advantages in the totality of their properties and, again, entail relatively high cost.

The third possibility to advance turbocharger technology and the associated concepts

– and the one doubtless offering the highest potential in technical terms – is a

20th Aachen Colloquium Automobile and Engine Technology 2011 19

combination of charging systems, such as combining two turbochargers or one

turbocharger with a mechanically or electrically driven compressor. In purely

thermodynamic terms, these concepts offer considerable advantages, with no major

functional cross-effects – provided the overall systems are configured appropriately.

However, the integration of the overall concepts into the engine and vehicle package

demands considerable effort and expense, and – for small models in particular – is

often difficult or in some cases even impossible. Moreover, combination

turbocharging concepts are very costly, both in terms of the turbocharger

components themselves and also frequently in terms of peripheral on-board

components.

But since the greatest potential in future is expected to be realised by advances in

turbocharging technologies, there will no doubt be fierce competition among the

various concepts, and those offering the best cost/benefit ratio will win through.

However, as turbocharging increases further, and thus more downsizing is

implemented, one problem will arise. The ever greater knock limitation, reduced

compression ratios and increasing charge cycle losses will almost certainly lead to a

rise in consumption under high load. This may result in increased consumption in

customer applications, depending on the vehicle model and driving habits, where

extreme downsizing concepts are implemented. Consequently, highly charged

concepts will necessitate additional measures especially in order to cut fuel

consumption under high load. In view of this, a combination with some of the

combustion methods presented in the previous section appears to be a most useful

solution.

4 Summary and Outlook

With the introduction of TFSI technology in 2004, Audi launched a new era in petrol

engine development. No engine technology other than TFSI has delivered such a

boost to performance and fuel efficiency in such a short time, and no other engine

technology has established itself on the market in such a short time (just five years!),

practically eliminating all other competing technologies in the process.

With the aid of turbocharging and TFSI technologies, the CO2 emissions of Audi and

VW Group models have been significantly reduced over the last 15 years, while

performance has been greatly improved.

The new 1.8l TFSI in 2011 marks the launch of the third generation of the successful

TFSI technology from Audi. Alongside extensive modification and optimisation of the

engine, in this third generation of the four-cylinder inline TFSI engines Audi has once

again introduced a wide range of new and innovative technologies – some of them

being put into mass production for the first time.

The technical highlights of the new engine generation:

Electronic coolant thermostat

20 20th Aachen Colloquium Automobile and Engine Technology 2011

Cylinder head with integrated exhaust manifold

Electric wastegate actuator

Dual injection system

With the third generation of TFSI engines, significant progress has once again been

made compared with the already very well positioned second generation of the

EA888 engine series, thus further strengthening the outstanding position of the fourcylinder inline TFSI engine range in the competitive environment. The new 1.8l

EA888 TFSI engine without doubt represents a further milestone in Audi’s downsizing

and downspeeding strategy.

TFSI technology will continue to offer wide-ranging potential in future, particularly with

regard to cutting CO2 emissions. Key technologies in this, from Audi’s viewpoint, will

be advances in turbocharging technology and the introduction of new combustion

methods.

20th Aachen Colloquium Automobile and Engine Technology 2011 21

5 References

[1] Krebs, R.; Böhme, J.; Dornhöfer, R.; Wurms, R.; Friedmann, K.; Helbig, J.;

Hatz, W.

Der neue AUDI 2,0T FSI Motor – Der erste direkteinspritzende Turbo-Ottomotor

bei AUDI [The new Audi 2.0T FSI engine – the first direct-injection turbocharged

petrol engine from Audi]

25th Vienna Engine Symposium 2004, Vienna 2004

[2] Wurms, R.; Kuhn, M.; Zeilbeck, A.; Adam, S.; Krebs, R.; Hatz, W.

Die Audi Turbo FSI Technologie [The Audi turbo FSI technology]

13th Aachen Colloquium on Vehicle and Engine Technology, Aachen 2004

[3] Böhme, J.; Hatz, W.; Eiser, A.; Dornhöfer, R.; Ehret, W.; Wurms, R.

Der neue R4-1,8l T-FSI-Motor von AUDI [The new four-cylinder inline 1.8l TFSI

engine from Audi]

15th Aachen Colloquium – Vehicle and Engine Technology, Aachen 2006

[4] Dornhöfer, R.; Hatz, W.; Eiser, A.; Böhme, J.; Adam, S.; Unselt, F.; Cerulla, S.;

Zimmer, M.; Friedmann, K.; Uhl, W.

Der neue R4 2,0l 4V TFSI-Motor im AUDI S3 [The new four-cylinder inline 2.0l

4V TFSI engine in the Audi S3]

11th Supercharging Conference, Dresden 2006

[5] Eiglmeier, C.; Pfalzgraf, B.; Helbig, J.; Adam, S.; Grigo, M.; Dornhöfer, R.;

Eiser, A.

Der neue R4 – 2,0l TFSI SULEV/PZEV-Motor von AUDI [The new four-cylinder

inline 2.0l TFSI SULEV/PZEV engine from Audi]

16th Aachen Colloquium on Vehicle and Engine Technology, Aachen 2007

[6] Wurms, R.; Budack, R.; Böhme, J.; Dornhöfer, R.; Eiser, A.; Hatz, W.

Der neue 2.0L-TFSI mit Audi valvelift system für den Audi A4 – die nächste

Generation der Audi Turbo-FSI-Technologie [The new 2.0l TFSI with Audi

valvelift system for the Audi A4 – the next generation of Audi turbo FSI

technology]

17th Aachen Colloquium – Vehicle and Engine Technology, Aachen 2008

[7] Ballauf, J.; Hatz, W.; Eiser, A.; Dornhöfer, R.; Grigo, M.; Ewald, A.; Stichlmeir,

M.

Audi 2.0l TFSI flexible fuel

12th Conference on The Working Process of the Combustion Engine, Technical

University of Graz, 24/25 September 2009

[8] Heiduk, T.; Dornhöfer, R.; Eiser, A.; Grigo, M.; Pelzer, A.; Wurms, R.

“Die neue Motorgeneration des R4 TFSI von Audi” [The new four-cylinder inline

TFSI engine generation from Audi]

32nd Vienna Engine Symposium 2011, Vienna 2011

22 20th Aachen Colloquium Automobile and Engine Technology 2011